Lifting platforms

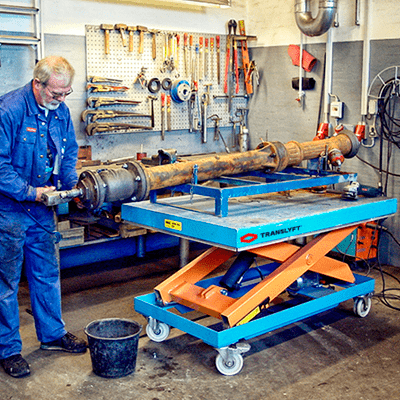

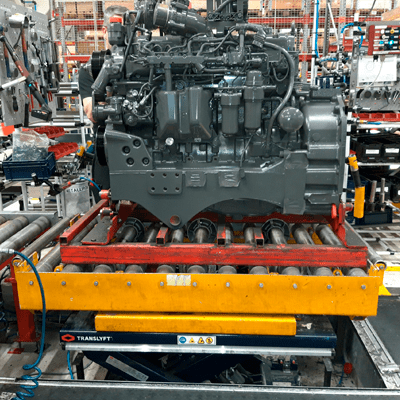

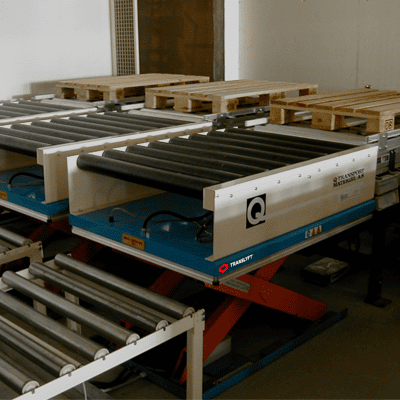

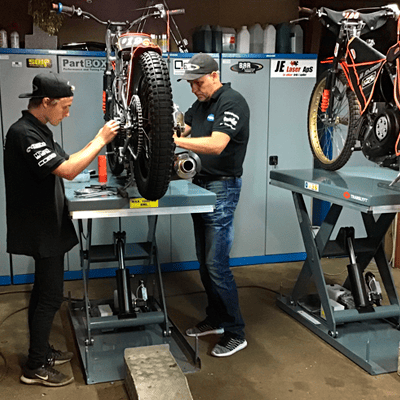

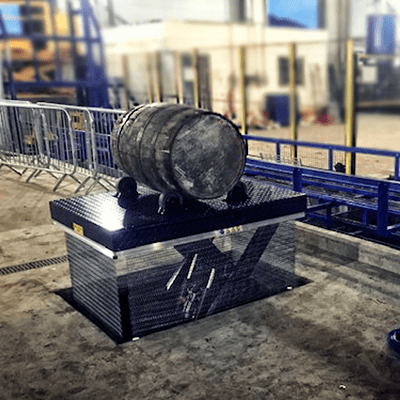

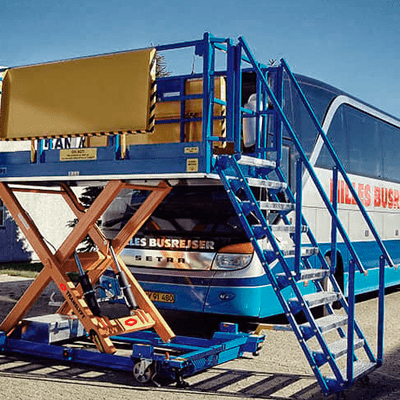

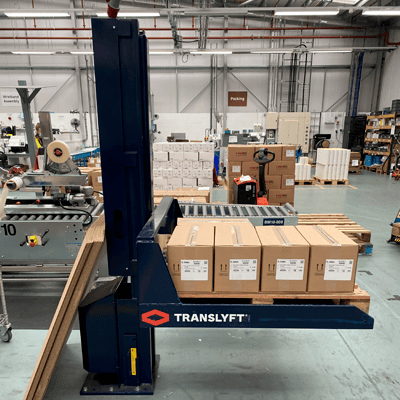

Lifting platforms, also known as lifting tables or scissor lifts, are mechanisms used for elevating goods or materials to a desired height for easier access and handling. They are commonly used in manufacturing, storage, and shipping facilities, as well as in construction sites and warehouses.

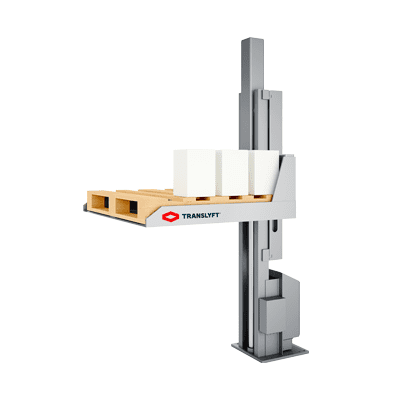

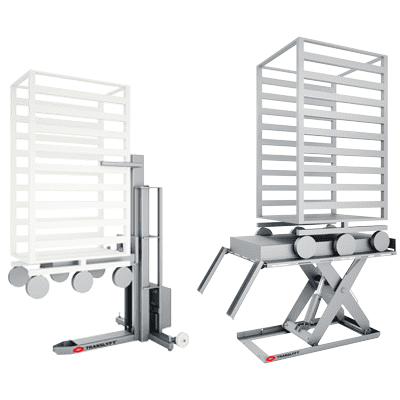

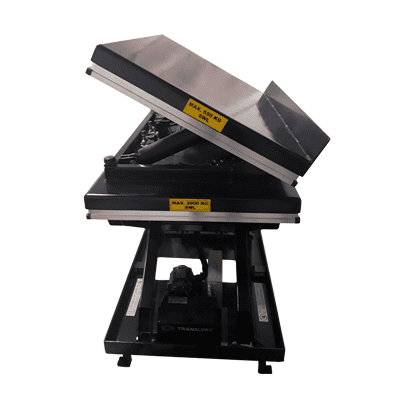

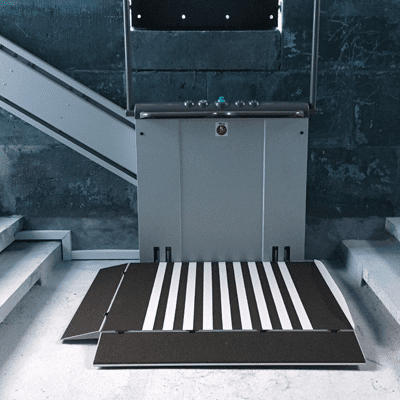

A lifting platform can be further classified based on their construction and design, including scissor lifts, platform lifts, and vertical mast lifts. Scissor lifts are the most commonly used type of lifting platform, as they are simple to operate, have a large platform, and can lift heavy loads. Platform lifts, also known as deck lifts, are designed to raise and lower flat platforms, while vertical mast lifts are used to lift and lower loads vertically.

When selecting a platform for lifting, it is important to consider the weight capacity, platform size, and height range required for your specific application. Other factors to consider include safety features, ease of operation, and durability. It is also important to ensure that the lifting platform you select meets industry safety standards, such as OSHA or LOLER regulations, to ensure that it is safe to use.